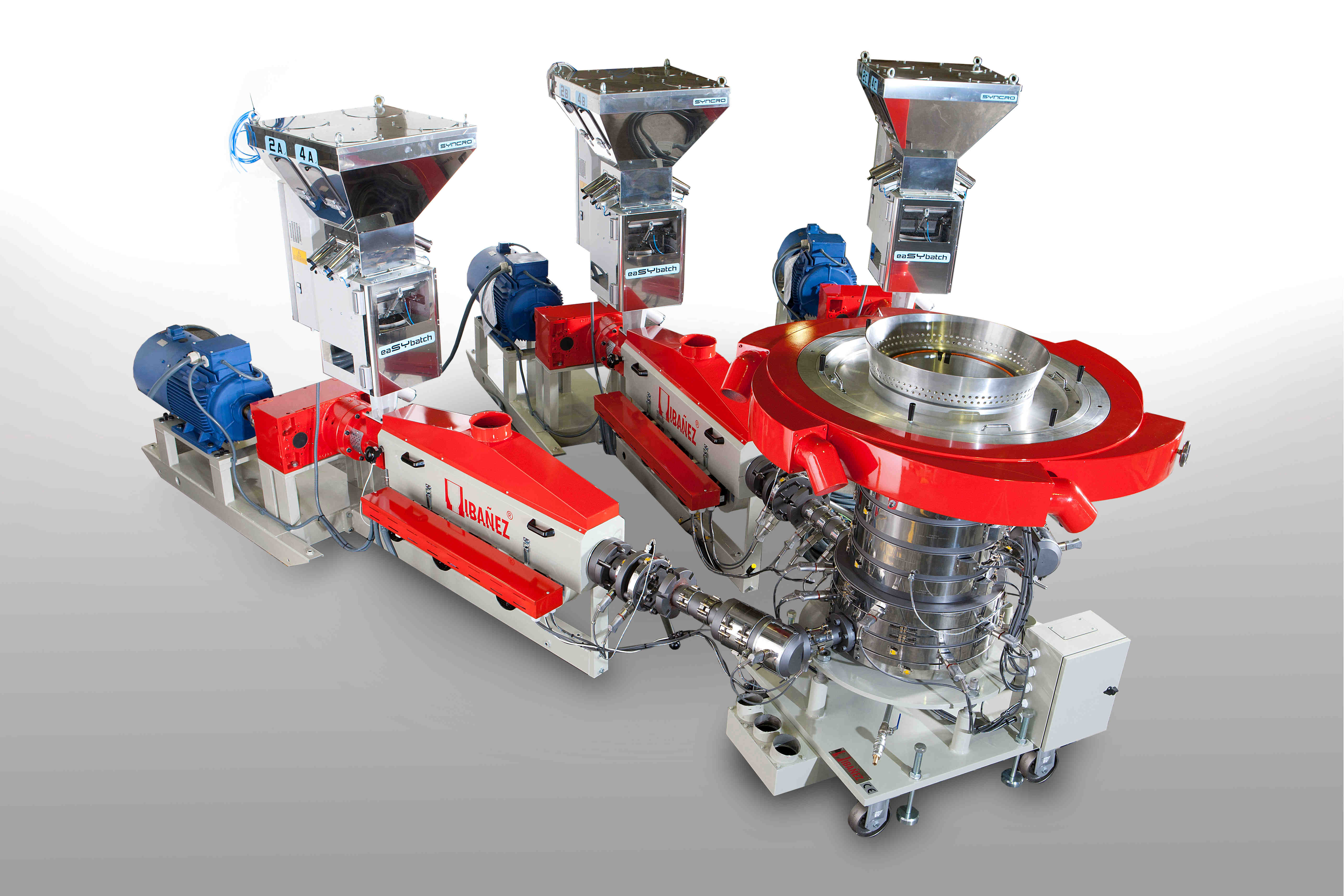

IBAÑEZ offers an ample spectrum of multilayer film or personal extrusion lines to adapt to the wide range of applications and capacities of manufacturing. Our lines are available in the number of layers that the client requires.

Lines which are able to produce a great variety of laminating films such as liquid packaging, barrier products, food industry products, healthcare products etc.

Our multilayer lines can incorporate advanced characteristics such as grooved alimentation, VISCO screws, gravimetric control, solid or liquid dosage (PIB), automatic changer, oscillating haul-off, IBC, automatic thickness control, etc.

CONTROL DEVICES:

Control of the weight of the material in g/m and dose in % of each of the components.

Manual and hydraulic screen changers.

Automatic thickness control placed on the air cooling ring

Film width and thickness meter devices.

Automatic guiding-band.

Web tension control through load cells.

Internal bubble cooling systems with width control via ultrasound sensors.

Automatic sheet cutting with bar feeder and hydraulic discharge coil.

Fully automatic winding station with bars feeder and hydraulic reels unloading system

The entire line is controlled by a PLC with field buses Device net and Ethernet

Remote supervision via internet and SCADA programme, running in an industrial fan-less PC with touch screen 15 / 17", 320 GB HHD.

Static electricity dischargers.

Completely personalized multilayer installations with all the possible controls to make co-extrusion an art.

High production capacity and high quality is what you obtain with our machines for whatever material composition and application that you may need to use.

Widths of up to 2500mm.

We offer advice about the best materials for your requirements.

At IBAÑEZ we build easily used cutting edge technology, sturdy and reliable machines.