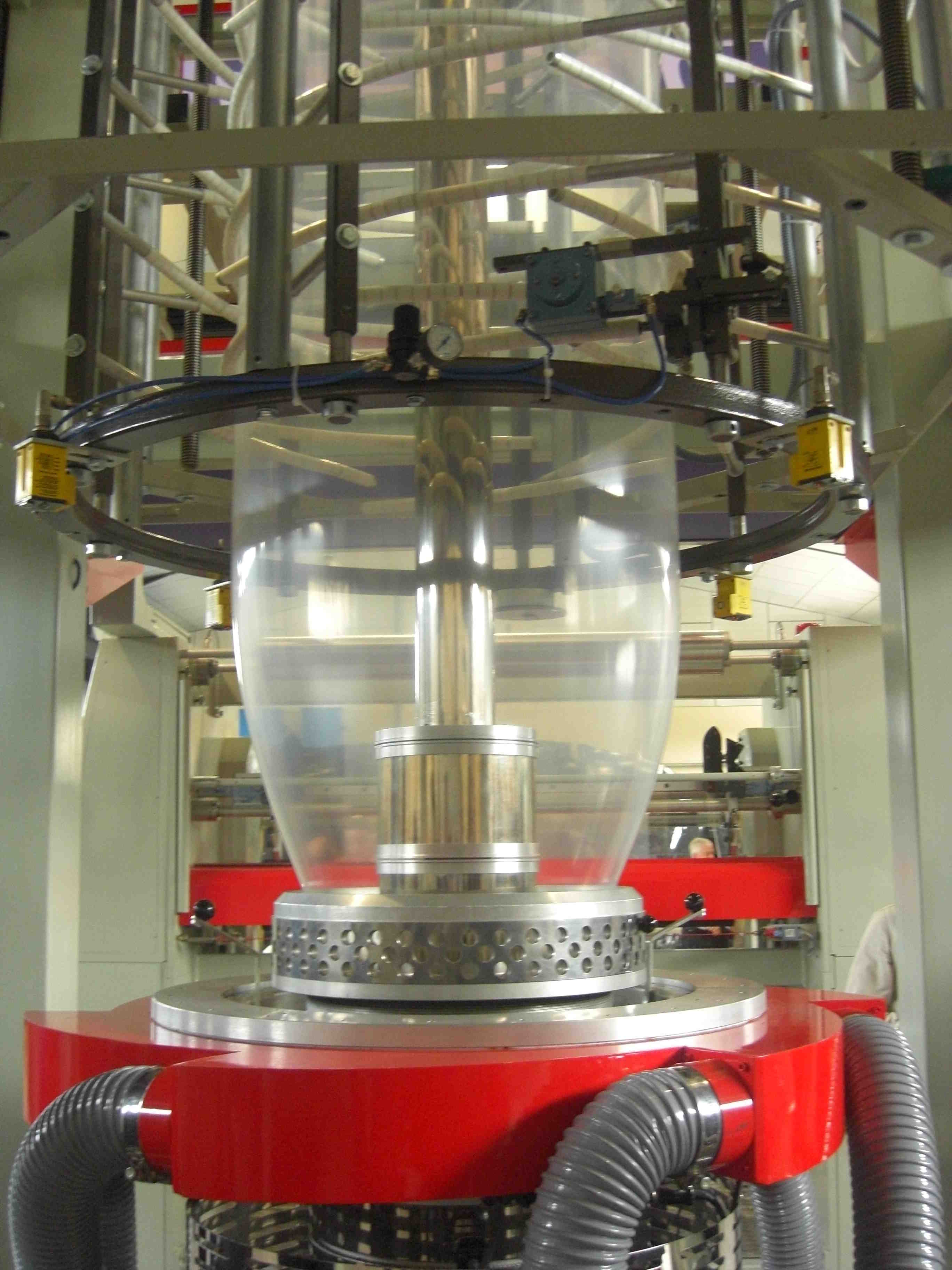

IBAÑEZ offers an ample range of personalized film production lines for LDPE/LLDPE, these are adapted to a wide spectrum of production applications and capacities.

Our production lines can incorporate advanced characteristics such as grooved alimentation, VISCO screws, gravimetric control, solid or liquid dosage (PIB), automatic screen changer, oscillating haul-off, IBC, thickness control, etc.

HIGH QUALITY COMPONENTS:

Standard high performance AC motors or torque motors that require no gearbox: long lasting intensity controlled ceramic heating resistors, protected against earth leakage in case of insulation failure; bimetallic long lasting mass produced screws; air cooling rings and IBC fans with frequency inverters; acclimatized electrical cabinets with automatic circuit-breakers, CE approved safety devices; dies designed to reduce and balance the time that the material spends in its interior, offering a balanced and large scale production. Horizontal or vertical rotating haul-off with precise speed and film tension control.

Complete LDPE / LLDPE installations, with an extrusion output of up to 120mm screw`s diameter, high performance and highly versatile.

Both in LDPE/LLDPE, the highest technology available is used when we build our machines.